Product Parameters

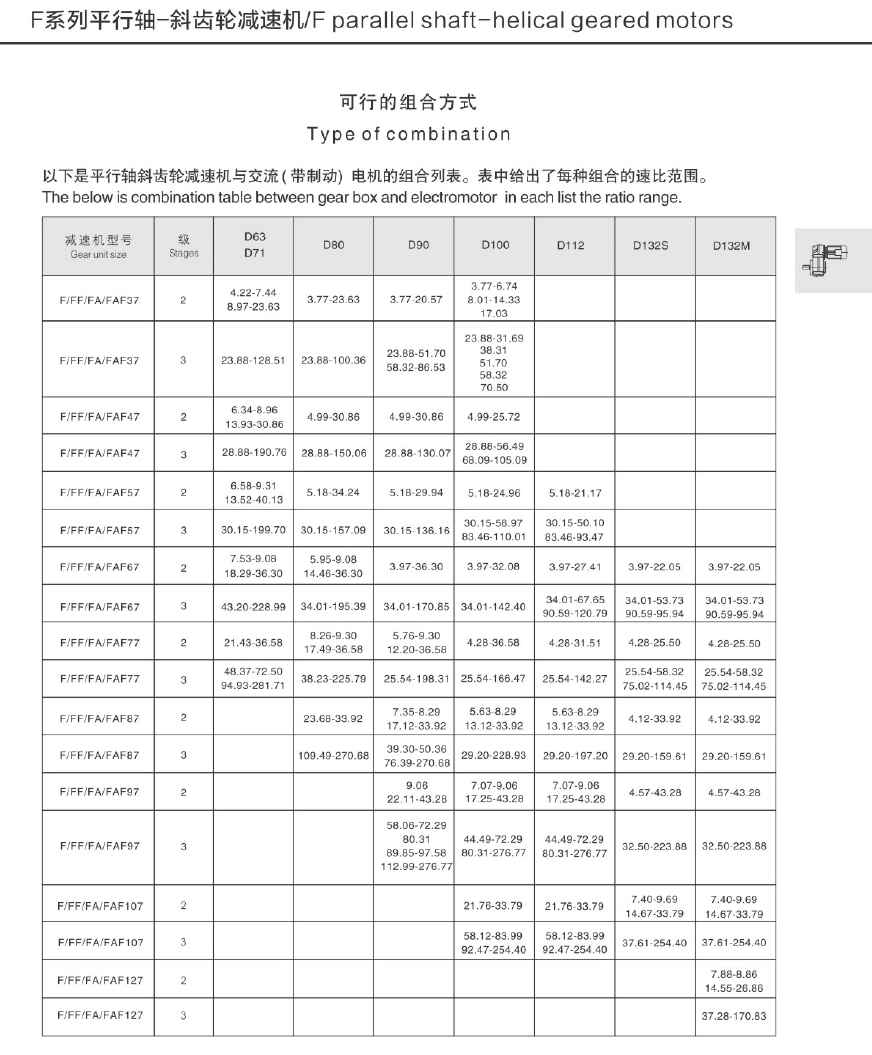

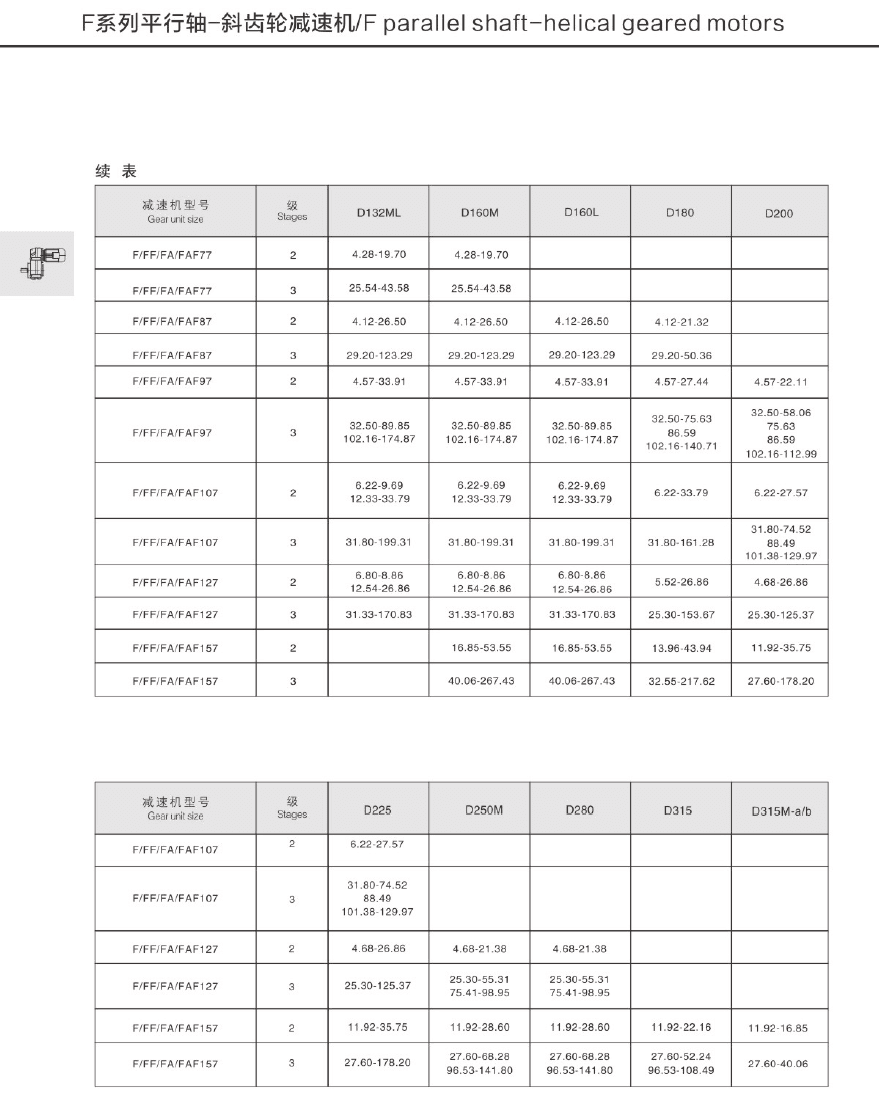

- Size: 37/47/57/67/77/87/97/107/127/157

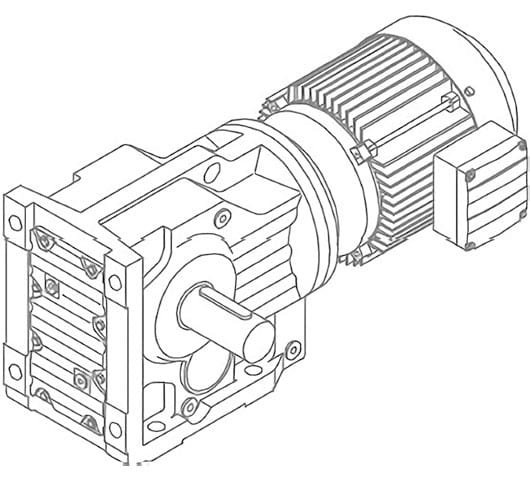

- Structural: F/FA/FF/FAF/FAZ

- Input Power Rating: 0.18-200KW

- Ratio: 3.81-280.76

- Allowable Torque: 200-18000 N·m

- Weight: 13-950 kg

Motor Models

Performance characteristics

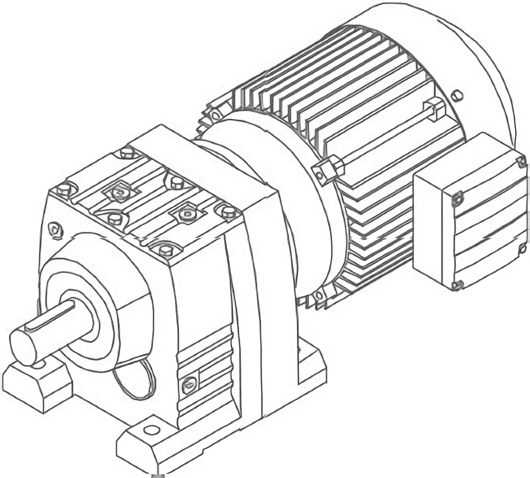

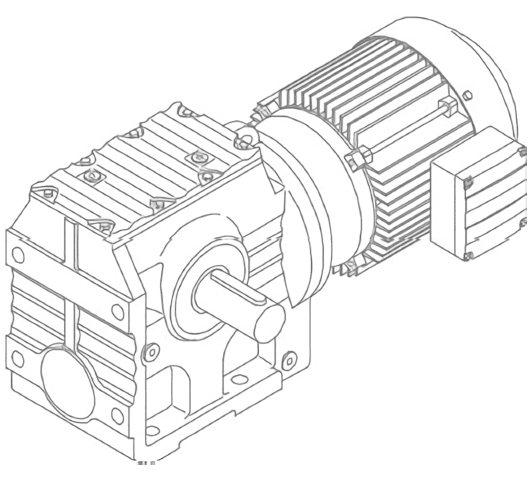

- The parallel shaft reducer, despite its slim design, can still provide a torque range of 130 to 18,000 Nm, making it an ideal choice for installations with limited space. It’s best suited for applications with confined installation areas, offering a variety of mounting positions and variants to meet diverse application needs under complex installation conditions while ensuring performance. This reducer also possesses inherent advantages: maintenance-free, ultra-long operational lifespan, and zero-wear gears with high fatigue strength.

- The parallel shaft helical gear reducer offers a rated torque from 130 Nm to 18,000 Nm and is highly efficient, making it suitable for a wide range of conveying and processing applications. It is available with foot mounting, flange mounting, or shaft mounting options. The low-backlash parallel shaft helical gear reducer can be used for precise positioning control.

- Utilizing a modular concept, the F series reducer can be connected to an AC motor to form the F..DR.. parallel shaft geared motor or to a servo motor to form the F..CMP parallel shaft helical gear servo reducer. Alternatively, you can select an AC motor or servo motor that meets your specific requirements

Applications

Conveyor Applications:

- Chain Conveyor

Process Applications:

- Press

- Extruder

- Screw Conveyor

- Gantry Crane

Product Details

Please refer to the R helical gear motor

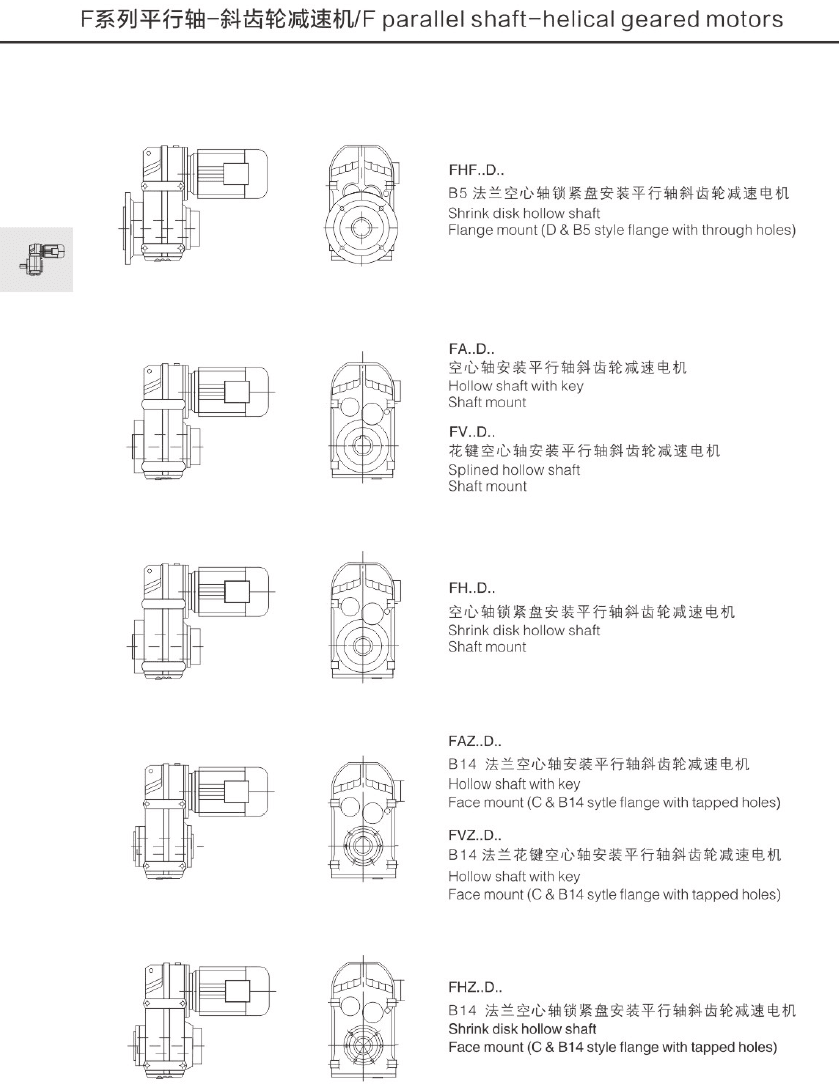

Basic models of F series parallel shaft helical gear reducers:

- Solid shaft output type: F37, F47, F57, F67, F77, F87, F97, F107, F127, F157

- Hollow shaft output type: FA37, FA47, FA57, FA67, FA77, FA87, FA97, FA107, FA127, FA157

- Solid shaft with flange output type: FF37, FF47, FF57, FF67, FF77, FF87, FF97, FF107, FF127, FF157

- Hollow shaft with flange output type: FAF37, FAF47, FAF57, FAF67, FAF77, FAF87, FAF97, FAF107, FAF127, FAF157

- Hollow shaft with small flange output type: FAZ37, FAZ47, FAZ57, FAZ67, FAZ77, FAZ87, FAZ97, FAZ107, FAZ127, FAZ157

- Solid shaft input solid shaft output type: FS37, FS47, FS57, FS67, FS77, FS87, FS97, FS107, FS127, FS157

- Solid shaft output combination type: F37R17, F47R17, F57R37, F67R37, F77R37, F87R57, F97R57, F107R77, F127R77, F127R87, F157R97

- Solid shaft input hollow shaft output type: FAS37, FAS47, FAS57, FAS67, FAS77, FAS87, FAS97, FAS107, FAS127, FAS157

- Hollow shaft output combination type: FA37R17, FA47R17, FA57R37, FA67R37, FA77R37, FA87R57, FA97R57, FA107R77, FA127R77, FA107R77, FA127R77, FA127R87, FA157R97

- Solid shaft with flange output type: FFS37, FFS47, FFS57, FFS67, FFS77, FFS87, FFS97, FFS107, FFS127, FFS157

- Solid shaft with flange output combination type: FF37R17, FF47R17, FF57R37, FF67R37, FF77R37, FF87R57, FF97R57, FF107R77, FF127R77, FF107R77, FF127R77, FF127R87, FF157R97

- Solid shaft input hollow shaft with flange output type: FAFS37, FAFS47, FAFS57, FAFS67, FAFS77, FAFS87, FAFS97, FAFS107, FAFS127, FAFS157

- Hollow shaft with flange output combination type: FAF37R17, FAF47R17, FAF57R37, FAF67R37, FAF77R37, FAF87R57, FAF97R57, FAF107R77, FAF127R77, FAF107R77, FAF127R77, FAF127R87, FAF157R97

- Solid shaft input hollow shaft with small flange output type: FAZS37, FAZS47, FAZS57, FAZS67, FAZS77, FAZS87, FAZS97, FAZS107, FAZS127, FAZS157

- Hollow shaft with small flange output combination type: FAZ37R17, FAZ47R17, FAZ57R37, FAZ67R37, FAZ77R37, FAZ87R57, FAZ97R57, FAZ107R77, FAZ127R77, FAZ107R77, FAZ127R77, FAZ127R87, FAZ157R97

- F..D..:Solid shaft, Rail mount with tapped holes

- FA..B..D..:Hollow shaft with key, Rail mount with tapped holes

- FV..B..D..:Aplined hollow shaft, Rail mount with tapped holes

- FH..B..D..:Shrink disk hollow shaft, Rail mount with tapped holes

- FF..D..: Solid shaft, Flange mount (D & B5 style flange with through holes)

- FAF..D..: Hollow shaft with key, Flange mount (D & B5 style flange with through holes)

- FVF..D..:Hollow shaft with key, FLange mount (D & B5 style flange with through holes)

- FHF..D..: Shrink disk hollow shaft,

- FLange mount (D & B5 style flange with through holes)

- FA..D..:Hollow shaft with key, Shaft mount

- FV..D..: Splined hollow shaft, Shaft mount

- FH..D..:Shrink disk hollow shaft, Shaft mount

- FAZ..D..:Hollow shaft with key, Face mount (C & B14 style flange with tapped holes)

- FVZ..D..:Hollow shaft with key, Face mount (C & B14 style flange with tapped holes)

- FHZ..D..: Shrink disk hollow shaft, Face mount (C & B14 style flange with tapped holes)

Click to download: F Series Parallel Shaft – Helical Gear Reducer Parameter Description.

In this parameter description, you can find:

- F Series Parallel Shaft – Helical Gear Reducer Parameters

- F Series Parallel Shaft – Helical Gear Reducer Installation Dimensions

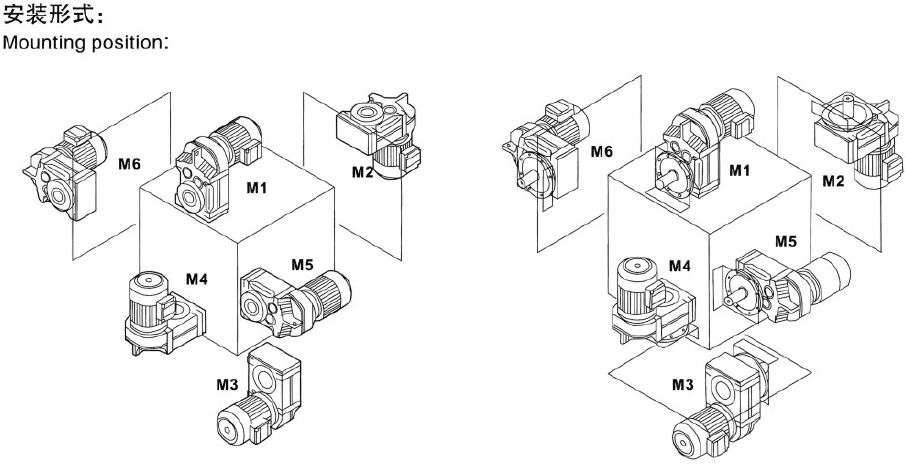

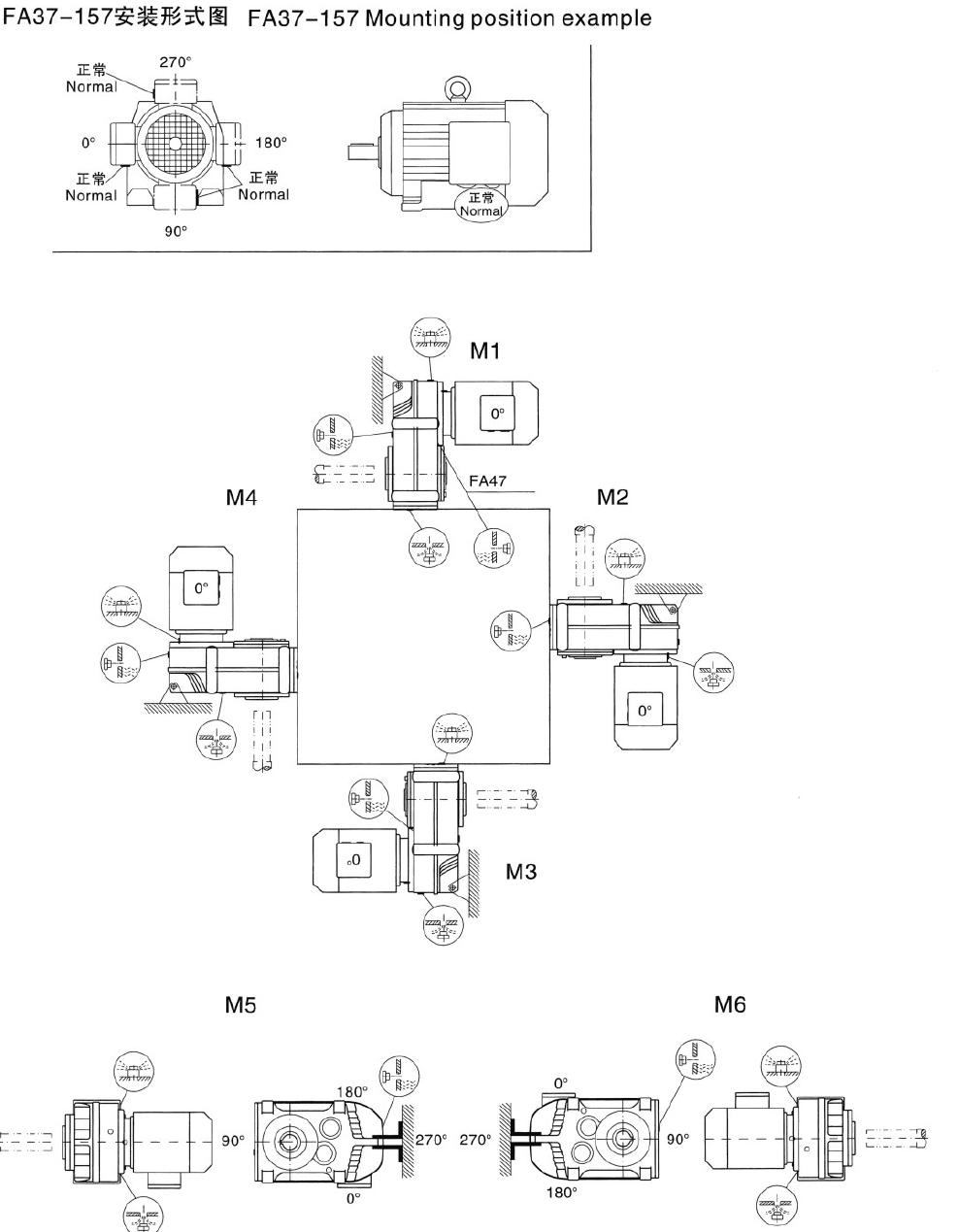

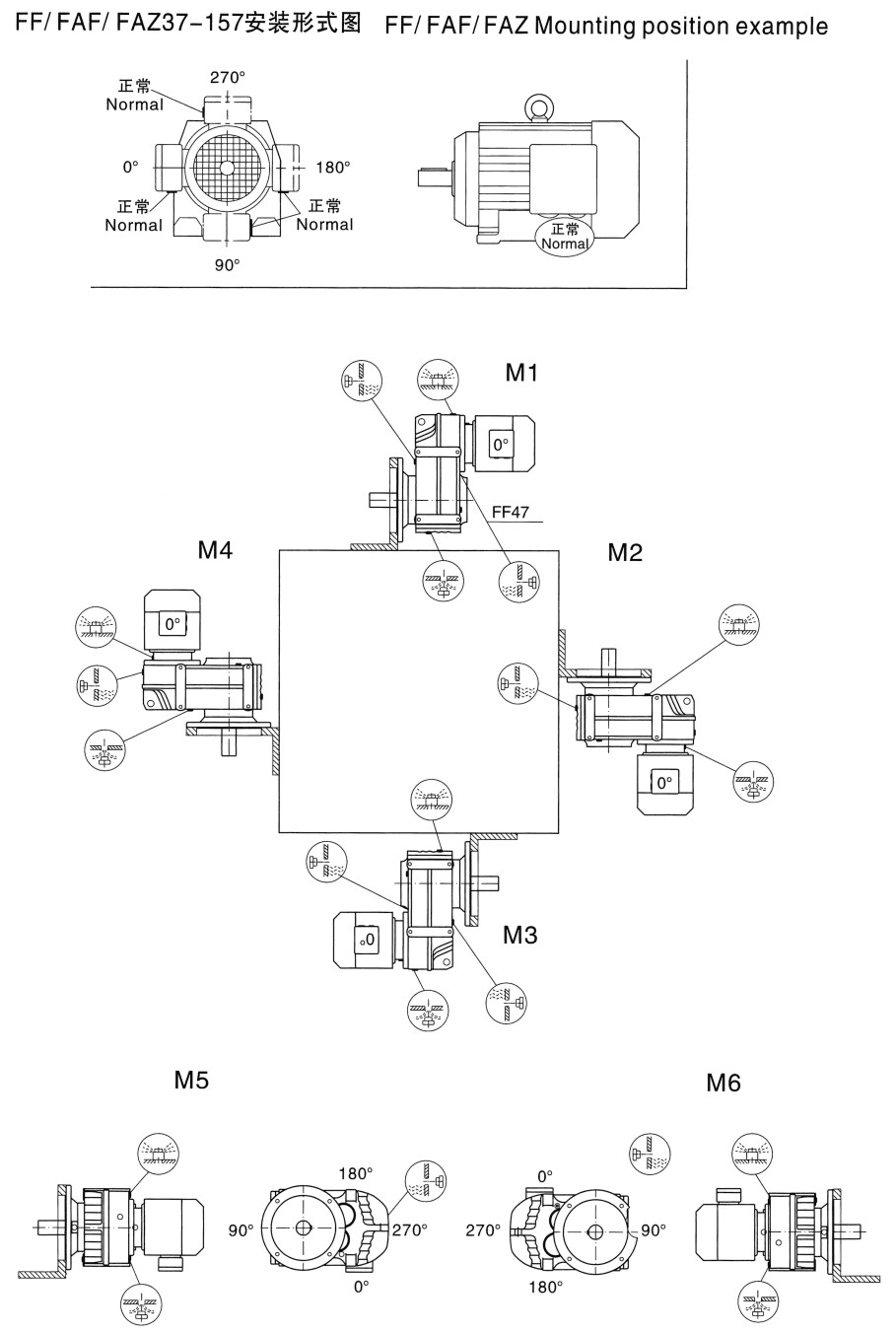

- F Series Parallel Shaft – Helical Gear Reducer Installation Type Diagrams

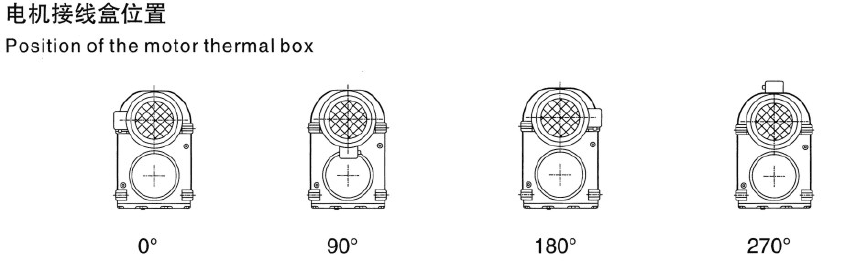

- F Series Parallel Shaft – Helical Gear Reducer Terminal Box Positions

- F Series Parallel Shaft – Helical Gear Reducer Input Power and Allowable Torque

- F Series Parallel Shaft – Helical Gear Reducer Weight Table

- F Series Parallel Shaft – Helical Gear Reducer Lubricant Quantity Table

Your trusted Gear Motors Manufacturer

HM Motor, established in 2005, is a leading enterprise specializing in designing, manufacturing, and distributing gear reduction motors. Our company steadfastly adheres to the business philosophy of “Quality as the foundation, Integrity as the root.” Through a scientifically sound quality management system and well-crafted market strategies, we continuously expand our product reach.

Our products have successfully penetrated markets across the nation, earning widespread acclaim from a diverse customer base. We pride ourselves on our highly skilled research and development team and state-of-the-art production facilities. Our products are characterized by stable performance, low noise operation, extended lifespan, and ease of maintenance. These qualities make them ideal for a wide range of applications, including logistics and conveying systems, mining and metallurgy, cement production, and packaging machinery.

At Hengming Intelligent, our mission is to provide our clients with products of exceptional value and quality, coupled with comprehensive after-sales support. We believe that by focusing on these core principles, we can achieve mutual success and growth with our partners and customers.

Our commitment to innovation, quality, and customer satisfaction positions us as a trusted name in the gear reduction motor industry. As we look to the future, we remain dedicated to pushing the boundaries of what’s possible in our field, always with an eye toward meeting the evolving needs of our clients and the industries we serve.