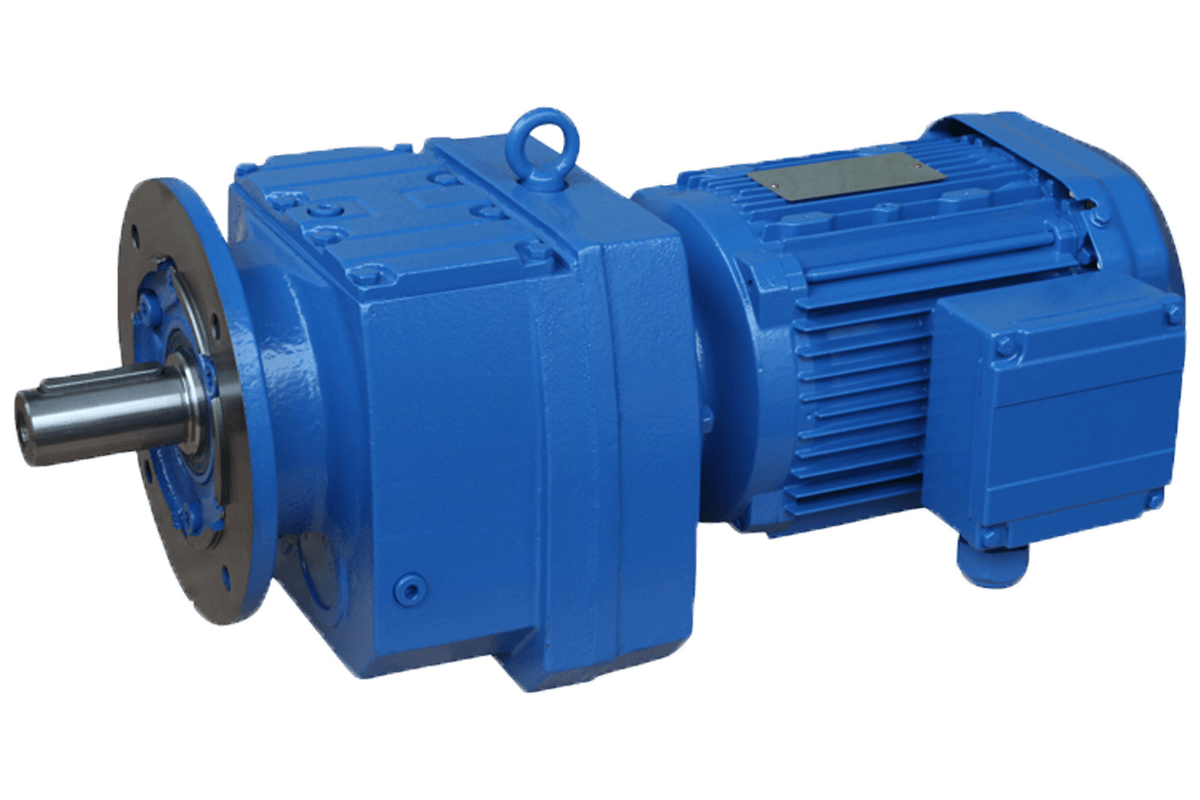

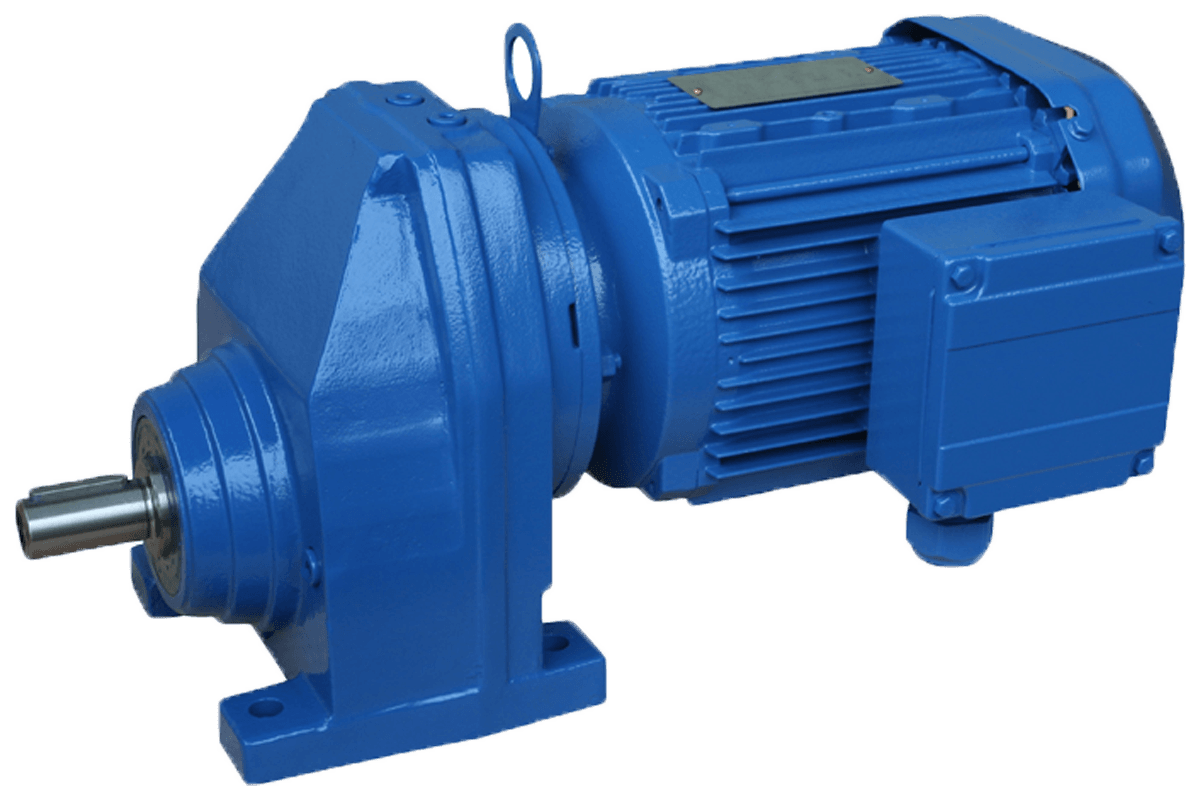

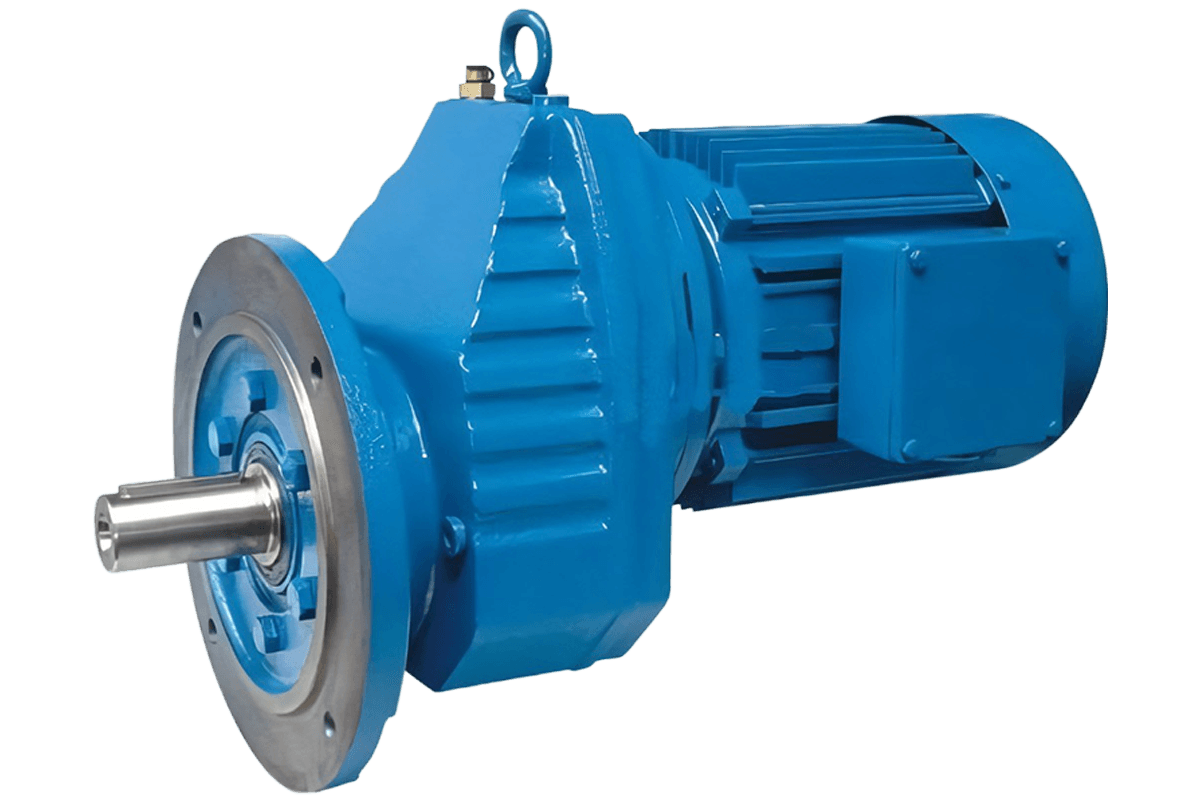

R Helical Geared Motor Summary

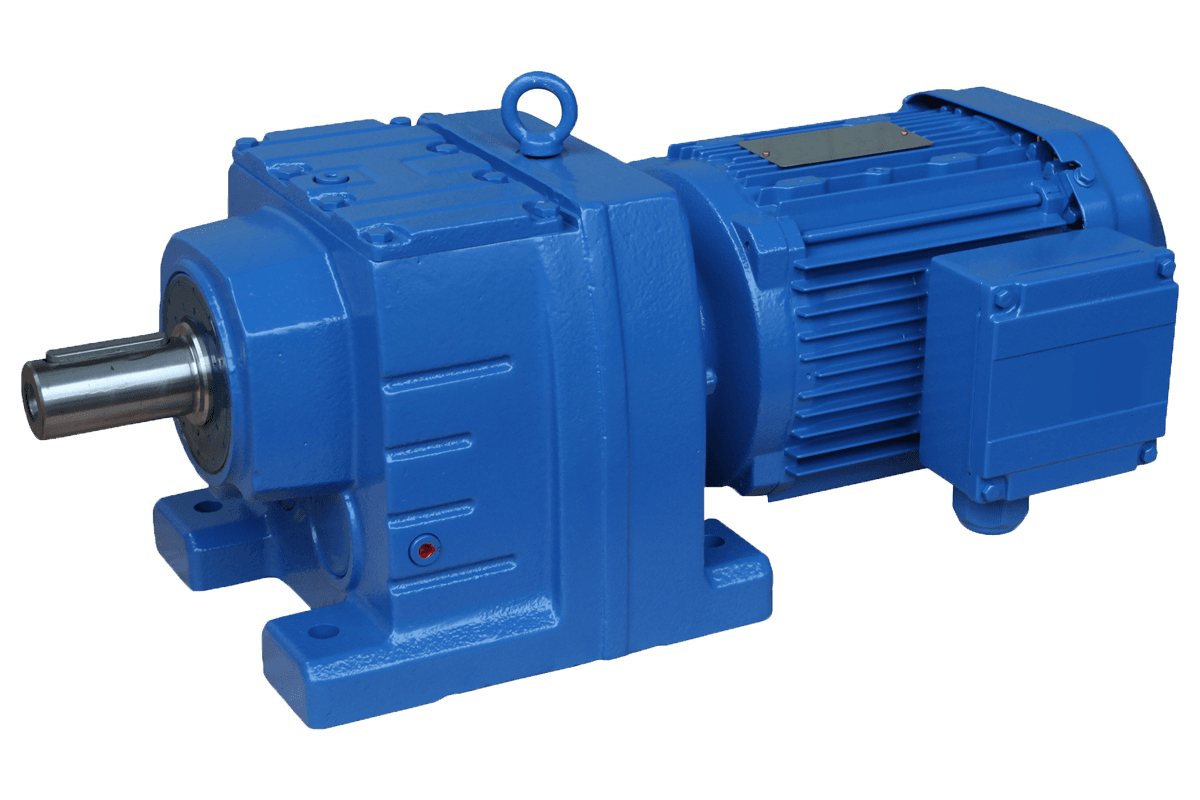

The R helical geared reducers hold a significant market share in modern industrial reducers. They are designed with a serialized and modular approach, offering broad adaptability with numerous motor combinations and installation options. The finely graded structure and transmission ratios make them suitable for various operating conditions, enabling seamless integration of mechatronics.

Advantages of choosing R series gear reducer

- This product features a serialized and modular design, offering broad adaptability. It provides a variety of motor combinations, installation positions, and structural schemes. The finely graded transmission ratios cater to different operating conditions and facilitate electromechanical integration.

- The R series helical gear hardened reducer is produced according to international technical standards, boasting high technological content.

- The hardened gear reducer is space-efficient, reliable, durable, and has a high overload capacity, with power reaching up to 132KW.

- It offers low consumption and superior performance, with an efficiency rating of 95% or higher.

- Designed for minimal vibration and low noise, it also promotes high energy savings.

- The R series helical gear hard tooth surface reducer is crafted from high-quality forged steel materials, with a rigid cast iron housing and gear surface that undergoes high-frequency heat treatment.

- After precision processing ensures the shaft’s parallelism and the positioning of bearings, the helical gear transmission assembly integrates with various motor types, forming a mechatronic system that guarantees the geared motor products’ quality and performance.

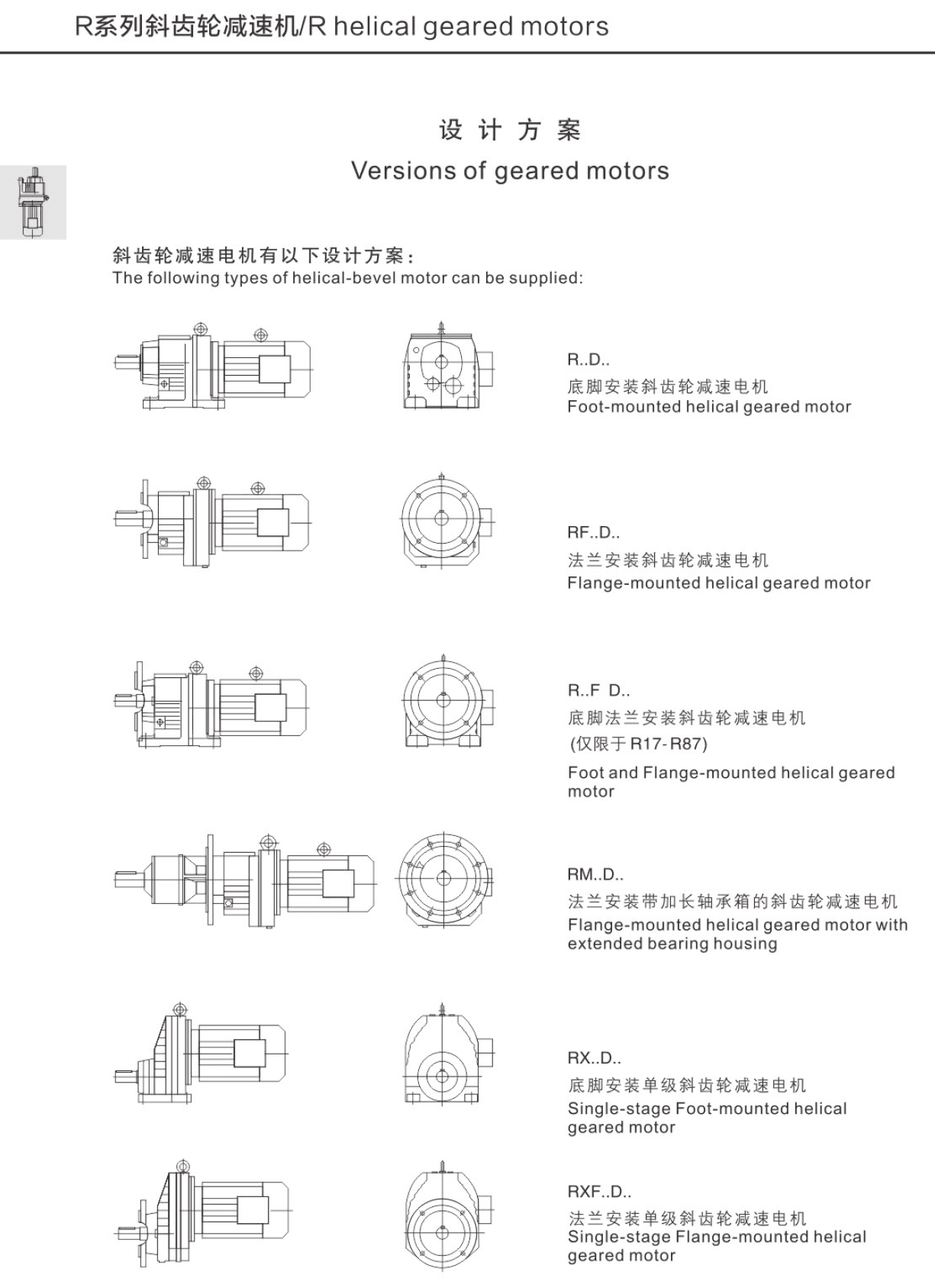

R Helical Geared Motors Models

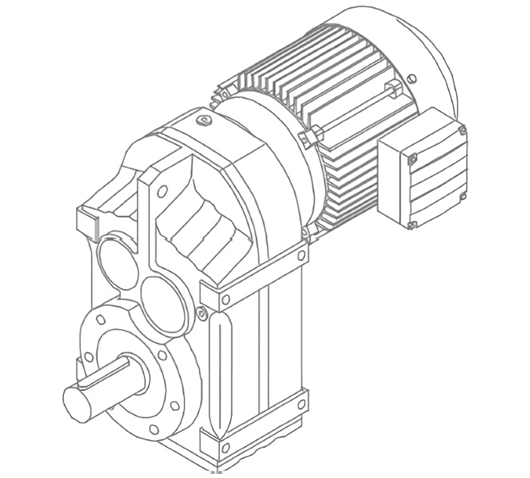

- R: Shaft extension type foot installation

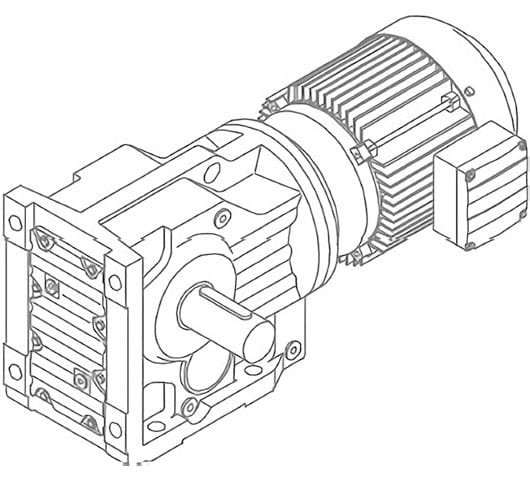

- RF: Flange installation

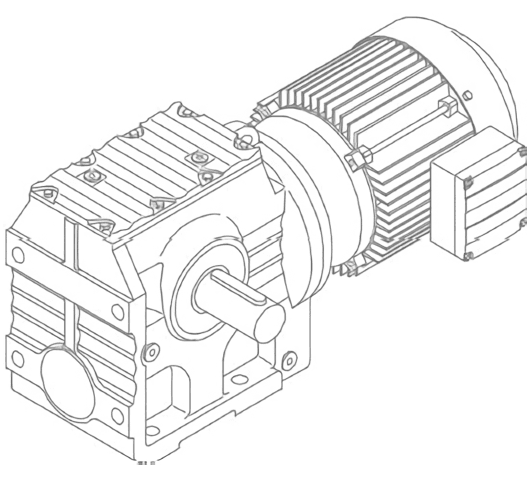

- R…F: Foot flange installation

- RM: Flange installation with extended bearing box

- RX: Single-step foot installation

- RXF: Single-step flange installation

Reducer model

- R17, R27, R37, R47, R57, R67, R77, R87, R97, R107, R137, R147, R167

- RF17, RF27, RF37, RF47, RF57, RF67, RF77, RF87, RF97, RF107, RF137, RF147, RF167

- RX37, RX57, RX67, RX77, RX87, RX97, RX107, RX127, RX157

- RXF37, RXF57, RXF67, RXF77, RXF87, RXF97, RXF107, RXF127, RXF157

- RS27, RS37, RS47, RS57, RS67, RS77, RS87, RS97, RS107, RS137, RS147, RS167

- R27R17, R37R17, R47R37, R57R37, R67R37, R77R37, R87R57, R97R57, R107R77, R137R77, R147R77, R147R87, R167R97, R167R107

- RFS27, RFS37, RFS47, RFS57, RFS67, RFS77, RFS87, RFS97, RFS107, RFS137, RF27R17, RF37R17, RF47R37, RF57R37, RF67R37, RF77R37,

- RF87R57, RF97R57, RF107R77, RF137R77, RF147R77, RF147R87, RF167R97, RF167R107

- RXS37, RXS57, RXS67, RXS77, RXS87, RXS97, RXS107, RXS127, RXS157

- RXFS37, RXFS57, RXFS67, RXFS77, RXFS87, RXFS97, RXFS107, RXFS127, RXFS157

Code Introduction

1、Product Code

- R-Helical Geared Motor

- F-Parallel Shaft-Helical Geared Motor

- K-Helical-Bevel Geared Motor

- S-Helical Worm Geared Motor

2、Installation Type

- No Code–Feet-mounted

- F–Flange-Mounted

- F–Feet and Flange-mounted

- M–Flange-mounted with extended bearing housing

- X–Single-stage Feet-mounted

- XF–Single-stage Flange-mounted

3、Gear Unit Size

67–Gear Unit Size 67

4、Flange Size

Ⅰ–No Code–No Flange or Only One Flange or The Smallest Flange

Ⅱ–Second Bigger Flange

Ⅲ–Biggest Flange

5、Electric Motor

- D–Three-phase asychronous motor (IP54)

- YB–Flame-proof three phase asychronous motor

- YGP–Table roller three-phase asychronous motor

- YZP–Metallurgy hoist frequency variable motor

- YVP–Frequency variable three-phase motor

- YD–Multi-speed three phase motor

6、Frame Size

80–Motor Center Height 80mm

7、Stator Length

D、K、N、S、M、ML、L

8、Number of Poles

4–4 Poles

9、Brake

No Code–No Brakes BMG–Brakes

10、Brake Release

- No Code–No Brake Release

- HF–Manual release(lock in the brake release position) Brake Release

- HR–Manual Release (automatic braking position)

11、Thermal Protection

- No Code–No Thermistor

- TF–Thermistor Sensor

- TF–Thermistor protection (PTC thermistor)

- TH–Thermostat protection (Blimetal switch)

12、Ratio

128.97–Ratio 128.97

13、Mounting Position

M1–Mounting Position M1

14、Terminal Box Position

- No Code–Terminal Box Position is 0°

- 180°–Terminal Box Position is 180°

Available Drive Motors

- General Motors of 1 Phase or 3 Phase AC

- Brake Motors

- Variable Frequency Variable Speed Motors

- Variable-pole Multi-speed Motors

- Explosion-proof Motors

- Permanent Magnet Motors

- DC Motors

- Servo Motors

- Brushless Motors

- Other Motors

Available Mounting Methods

- Foot Mounted

- Flange Mounted

- Shaft mounted

RXF57-RXF107 Mounting Position Example

R Series Helical Gear Reducer Detailed Parameters PDF: R Series Helical Gear Reducer PDF Information

Description:

– R Series Helical Gear Reducer Parameter Table: P13-P48

– R Series Helical Gear Reducer Installation Dimensions: P49-P70

– R Series Helical Gear Reducer Installation Diagram: P71-P76

Service Conditions

- Ambient Temperature: -40~50°C

- Altitude: 1000 m.a.s.l

- Working Duty: S1(Continuous)

- Humidity: ≦90%

- Cooling Method: Natural Cooling

- Lubrication: Oil-bath and Splash Lubrication (The lubrication should be heated above 0°C, if the temperature of machine is below 0°C when it start working)

- Suitable for normal-reverse rotation

- Waste water treatment

- Dredgers

- Metal working mills

- Conveyors

- Cranes

- Mixer

- Crusher

- Cooling towers

- Paper machine

- Cableways

- Cement industry

- Petroleum industry

- Textile machinery

- Food machine

- Power machine

- Construction machine

- Metallurgy machine

- Cement machine

- Water conservancy machine

- Chemical machine

- Mining machine

- Transportation machine

- Rubber machine

- Petroleum machine

- Other machines and industries