Micro Constant Speed Motor

6W Micro Constant Speed Motor

Product Features

The 6W micro fixed-speed motor has the following features:

- Compact Size: The 6W micro fixed-speed motor is small in size, making it ideal for use in space-constrained applications, such as small appliances, instruments, and meters.

- High Efficiency: This motor employs advanced fixed-speed technology, offering high power transmission efficiency and providing stable output power.

- Strong Stability: Constructed with high-quality materials and precision manufacturing processes, the 6W micro fixed-speed motor delivers excellent interference resistance and stability, ensuring consistent high performance during extended operation.

- Low Noise: Featuring a soundproof design and an optimized gear system, the motor effectively reduces noise, maintaining a quiet operating environment.

- Long Lifespan: HM Motor’s 6W micro fixed-speed motor is built with premium materials and precise manufacturing techniques, offering a long service life to meet the demands of prolonged, stable operation.

- High Reliability: As a professional manufacturer of micro fixed-speed motors, HM Motor draws on extensive production experience and advanced technical equipment to guarantee motor quality and reliability, delivering high-quality products and exceptional after-sales service to customers.

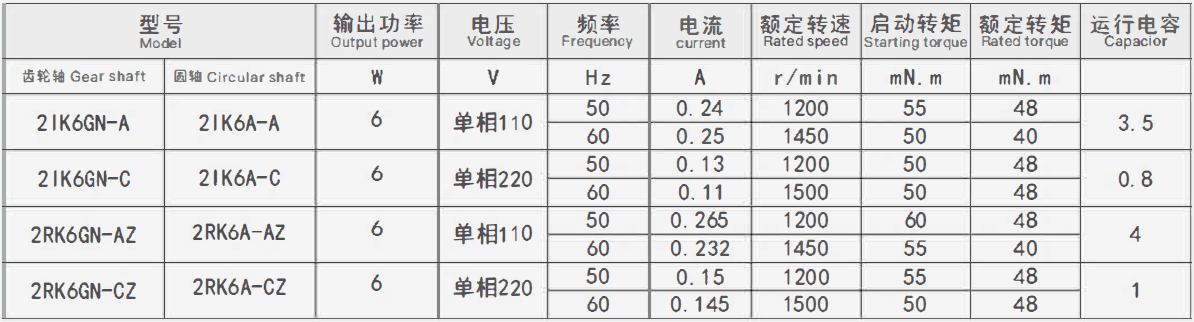

6W Miniature Constant Speed Motor Model/Performance

- The speed in the table is calculated by dividing the average speed of the motor by teh deceleration. The actual speed will vary with the load, ranging from 2 to 20%.

- The torque in the table is calculated by the rated torque x deceleration ratio x transmission efficiency of the motor.

- The maximum allowed torque of the reducer is 3N.m

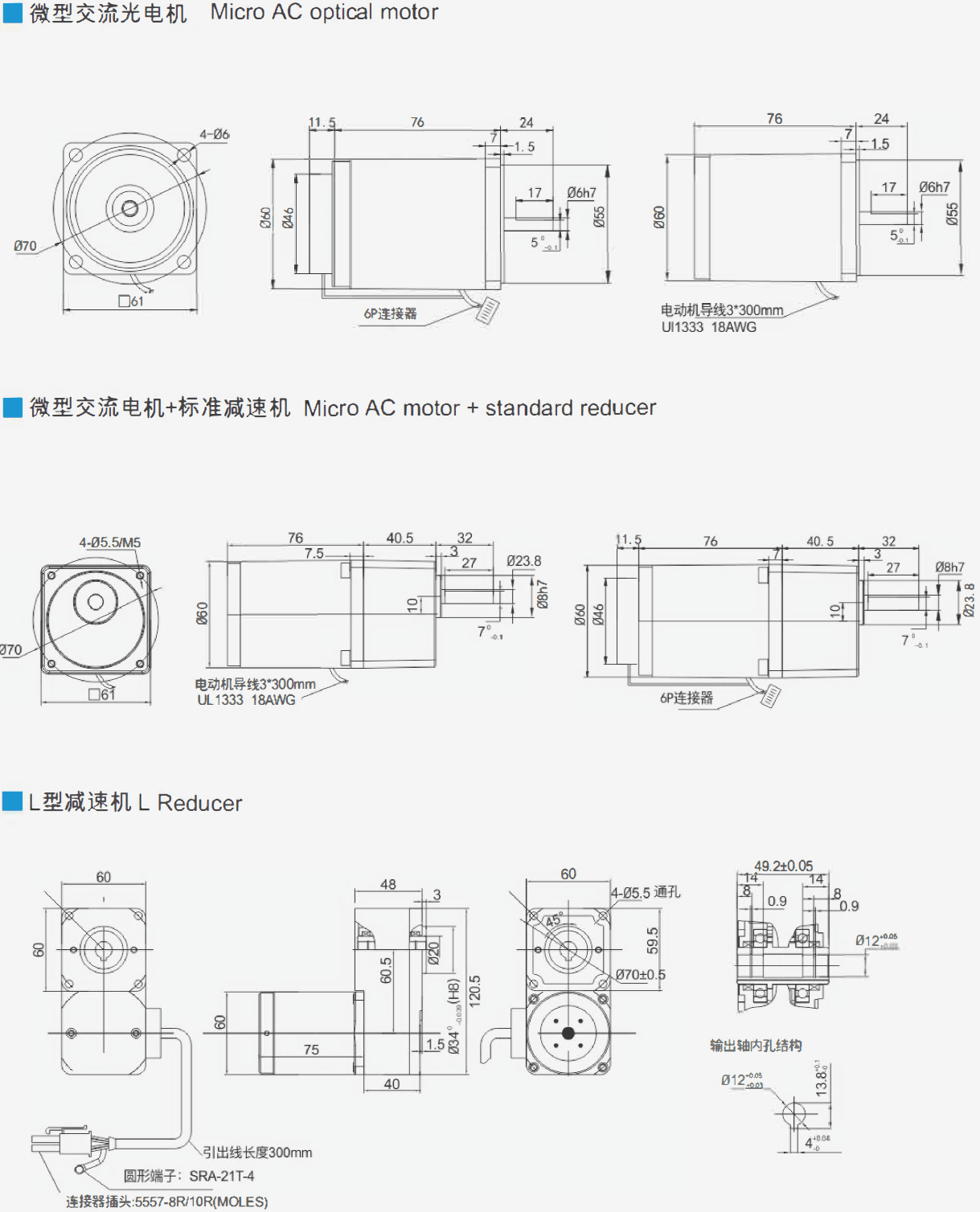

- Micro AC Optical Motor

- Micro AC Motor+Standard Reducer

- L Reducer

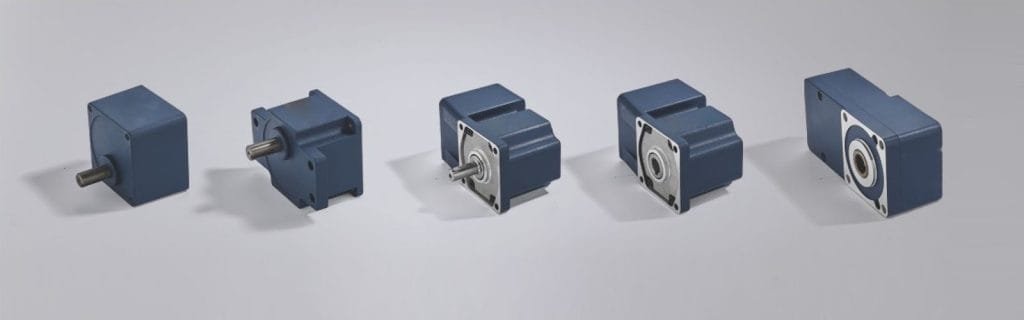

Small gear reduction motor series

Micro constant speed motor series models

“High Quality, High Standards, Zero Defects”

Our company unites a team of seasoned professionals with over 20 years of expertise in production, technology, and sales. Composed of passionate and driven individuals, we share a common vision. We are dedicated to innovation across technology, manufacturing, management, and processes. With a full range of imported and domestic production and testing equipment, our integrated industrial assembly line ensures quality and efficiency. Supported by a strong sales network and comprehensive after-sales service, we strive to provide exceptional products and support to all our customers.

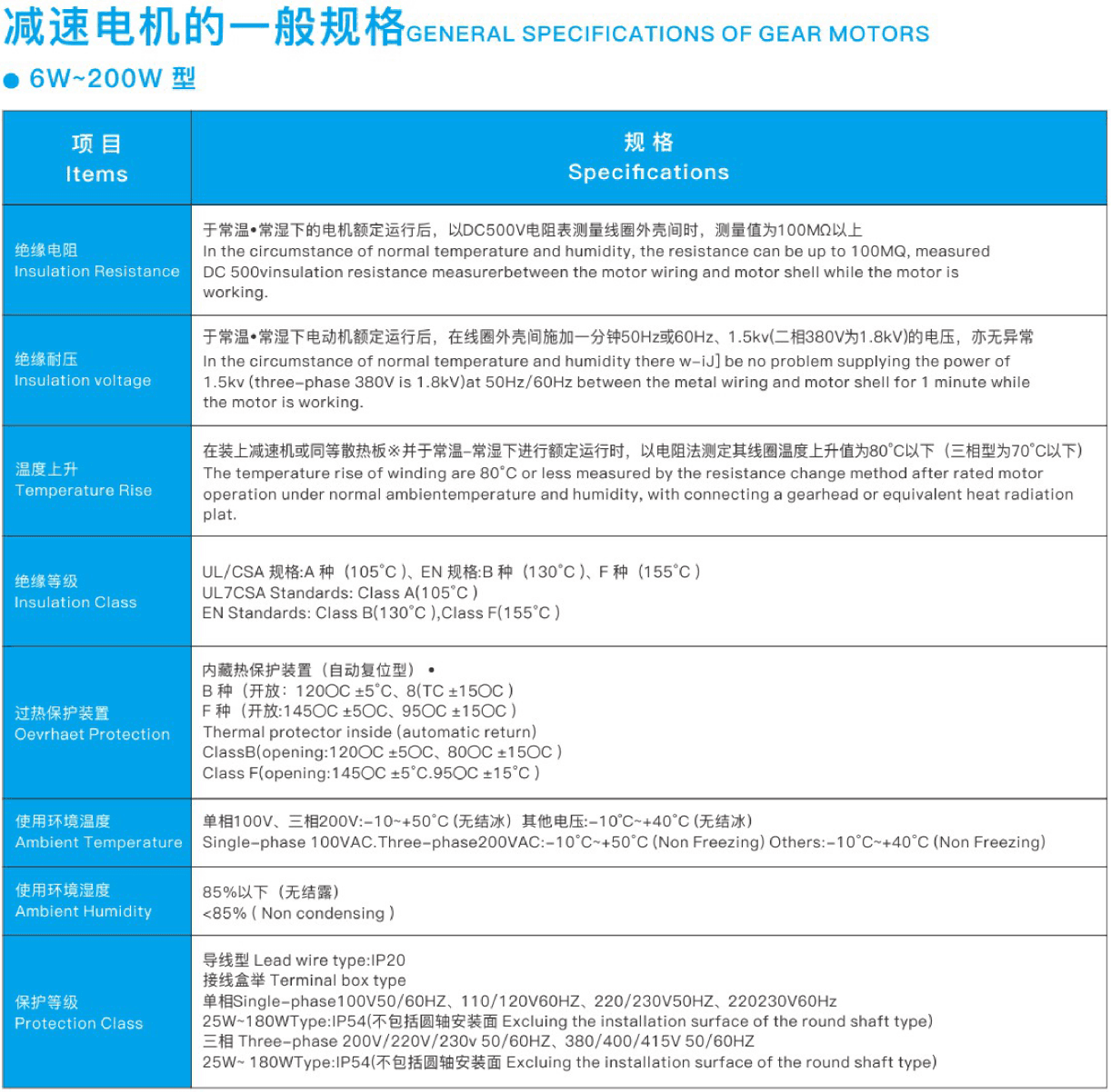

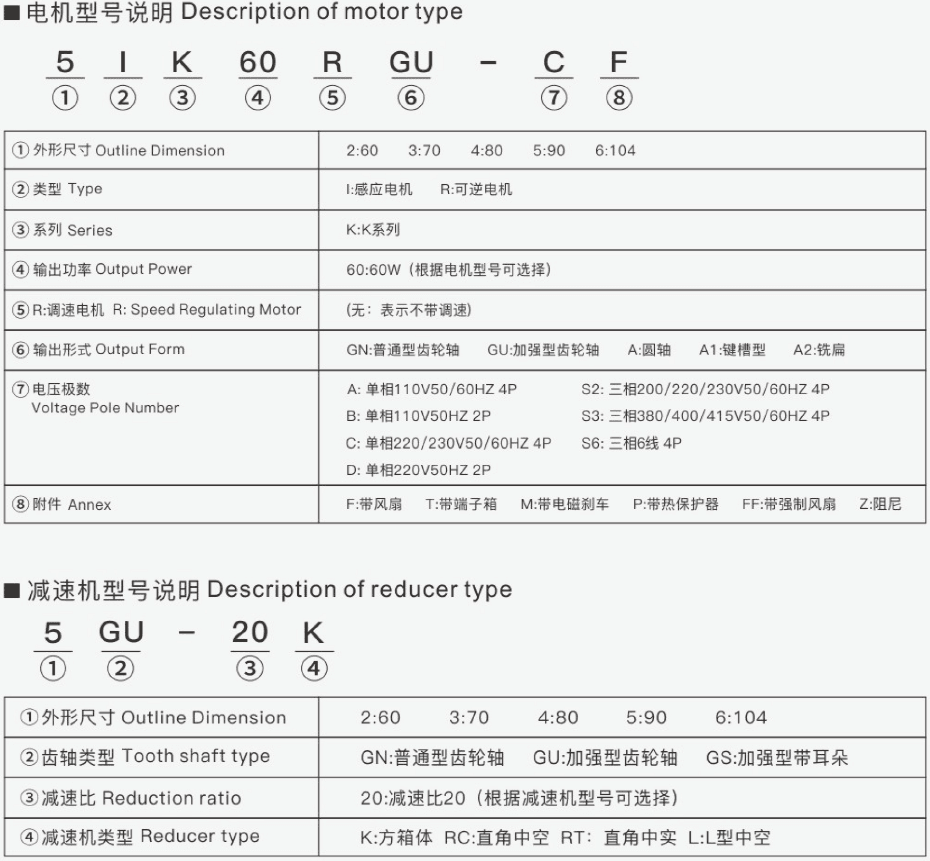

Reading method for specifications and models of micro constant speed motors

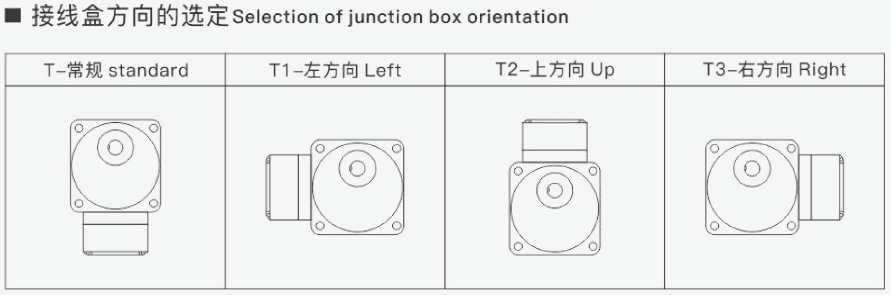

Selection of Junction Box Orientation

We Can Always Do Better

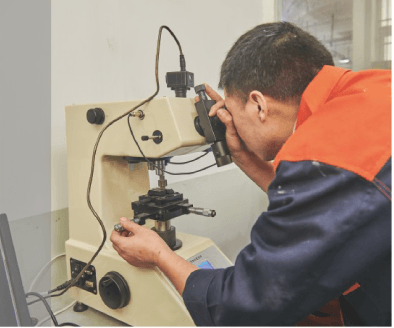

We focus on the details, enforcing strict quality control and robust process oversight to maintain high standards and prevent defects. Our comprehensive quality management system includes dedicated inspectors at every production stage, ensuring compliance with technical specifications. In the final inspection phase, skilled technicians conduct a full evaluation of each product’s appearance and performance, guaranteeing top-quality output before shipment.

Notes

Precautions for Installation and Use of Micro Constant Speed Motors

- General: Do not operate the gearbox or motor beyond the specifications on the nameplate or in the product catalog, as this may cause electric shock, injury, or damage to equipment. Avoid inserting fingers or objects into the gearbox or motor openings to prevent electric shock, injury, fire, or damage. Do not use a damaged gearbox or motor, which could result in injury or fire. Do not remove the nameplate. Unauthorized modifications by customers void the warranty, and our company assumes no liability.

- Handling: Exercise caution when moving the product, as dropping or tipping it poses significant risks.

- Installation: Keep flammable materials away from the gearbox and motor to prevent fire hazards. Ensure no objects block motor ventilation or cooling, as this could lead to burns or fire from overheating. Avoid touching the keyways of the gearbox or motor gears with bare hands to prevent injury. For applications like food machinery prone to oil leaks, attach an oil cup at the installation point to contain leaks and protect the product.

- Connection to Main Machinery: Equip rotating parts with safety covers to avoid injury. Confirm the rotation direction before connecting to other machinery, as incorrect rotation may cause injury or damage.

- Wiring: Do not touch terminals during insulation resistance testing to avoid electric shock.

- Operation: Connect to the power supply as per the wiring diagram or manual to prevent electric shock or fire. (For motors without a junction box, reinforce insulation at connection points.) Avoid Avoid excessive bending, stretching, or clamping of power cables or motor leads to reduce electric shock risks. Securely ground the grounding terminal to prevent electric shock. Use only the power supply specified on the nameplate to avoid motor burnout or fire.

- Daily Inspection and Maintenance: During operation, keep away from rotating parts (e.g., shafts) to avoid injury. In case of entanglement or injury, immediately switch off the power and respond promptly. During power outages, turn off the power switch to prevent injury or damage upon power restoration. Note: Motors with thermal protection will automatically shut off if overheated and restart once cooled, provided no damage has occurred.

- Inspection Upon Receipt: Confirm that the received product matches your order. Using the wrong product may damage the motor or equipment.

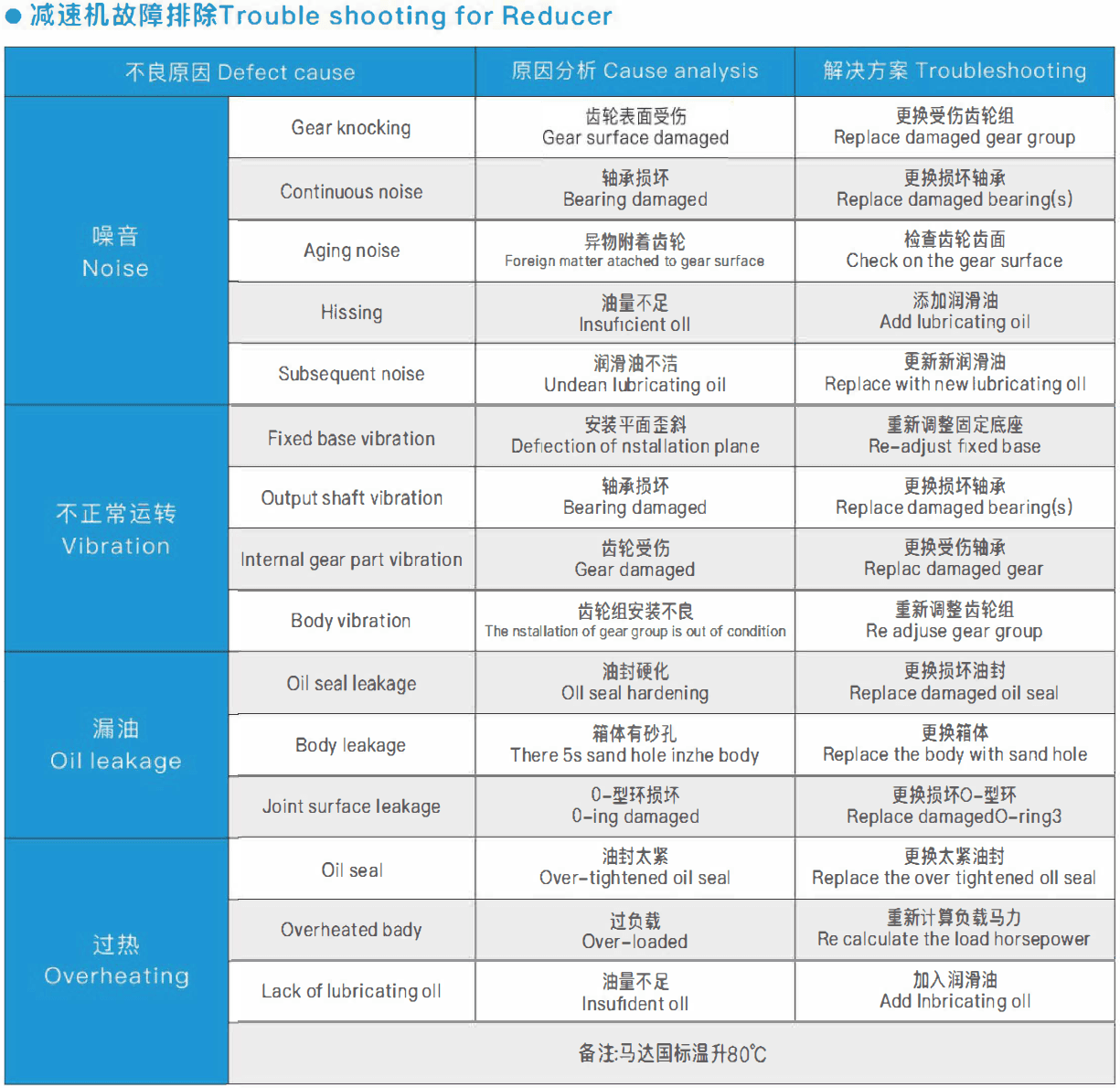

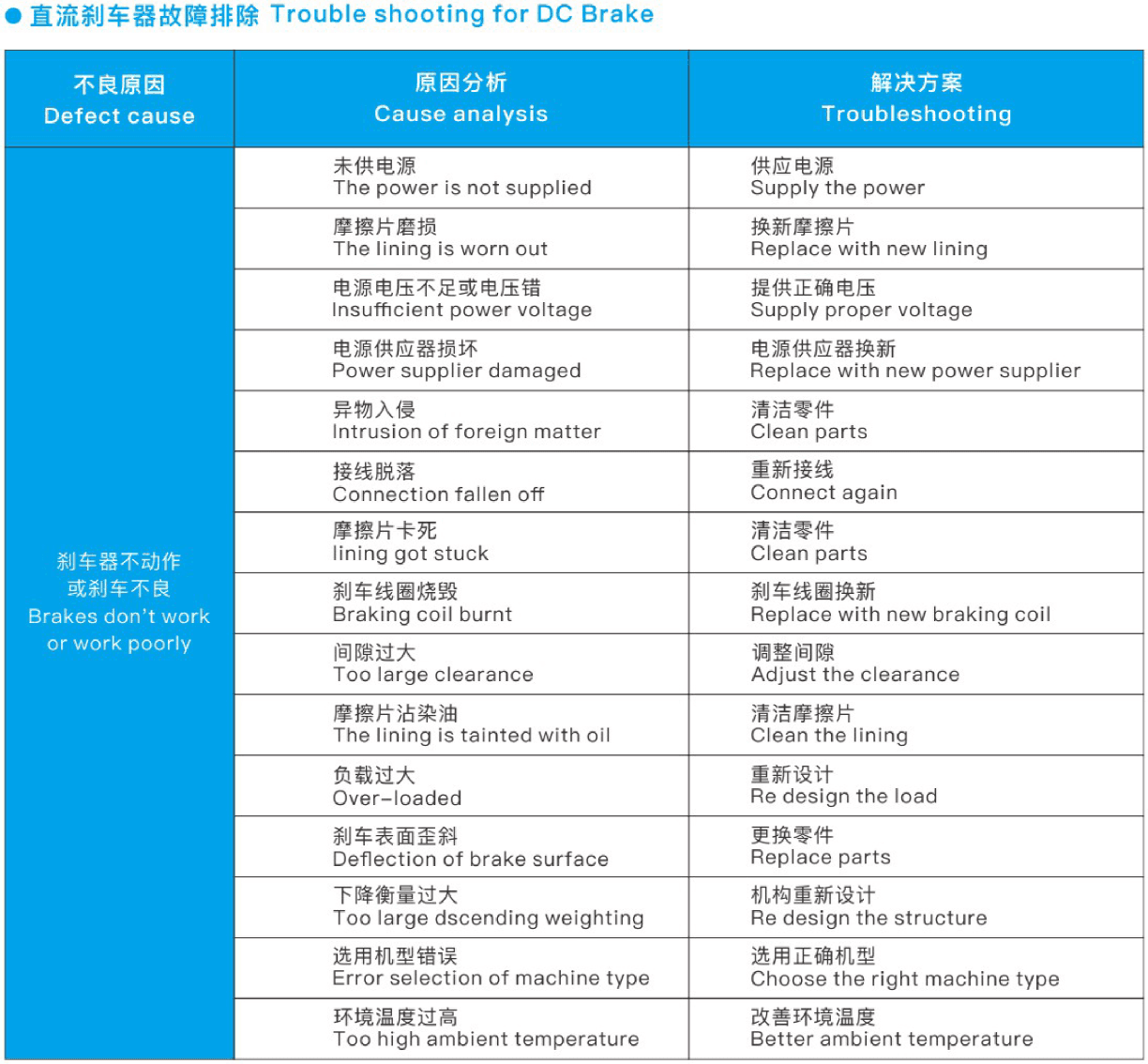

Trouble Shooting For Reducer