Products

60MM Series DC Brushless Gear Motor

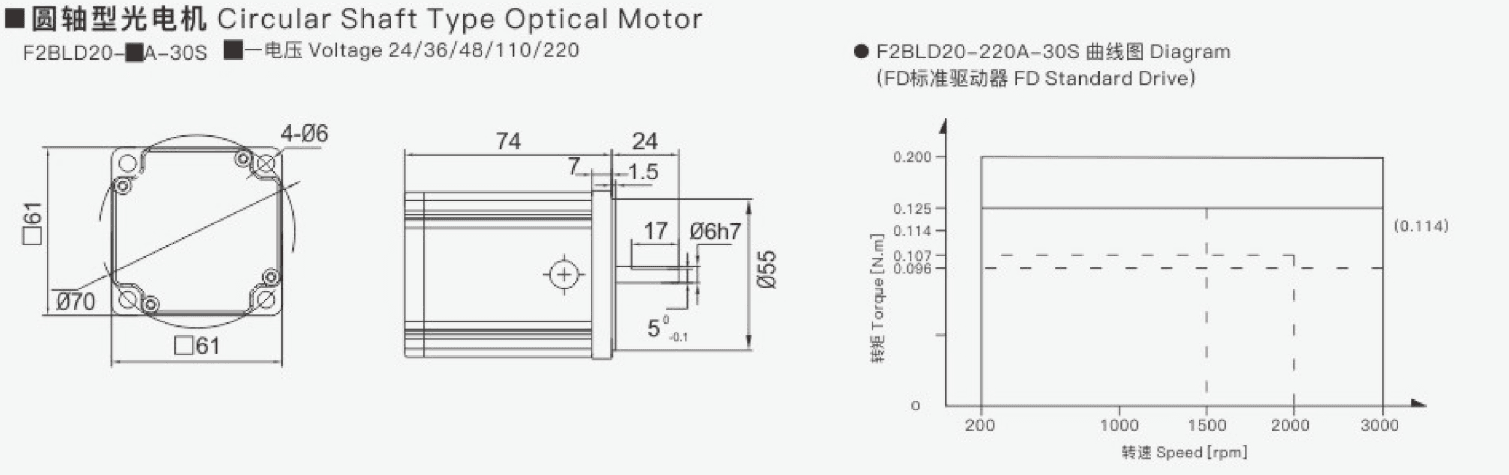

Basic Characteristics of Motor

- Rated power (continuous): 20W/40W

- Rated speed: 3000r/min

- Rated torque: 0.096 N.m

- Rotor moment of inertia: 0.042

- Speed control range: high pressure 200-2500RPM;

- Low voltage 200-3000RPM

DC Brushless Motor Manufacturer

Why Choose HM Motor?

HM Motor is a professional manufacturer of DC brushless reduction motors, established in 2005 and located in Shenzhen, Guangdong Province, China. The company adheres to the development concept of technology leading practice and innovation, and is committed to developing efficient, silent, stable and reliable DC motors.

HM Motor has years of research and manufacturing experience in the brushless motor industry, with a complete production process and quality control system. At present, the 60 series DC brushless reduction motors produced by the company are widely used in fields such as smart homes, smart devices, industrial automation, and medical equipment.

HM Motor focuses on the research and innovation of brushless motor technology, with an experienced technical team and advanced production equipment. The company is committed to providing customers with high-quality and high-performance DC brushless reduction motors to meet their needs to the greatest extent possible.

The advantages of Hengming intelligent devices are mainly reflected in the following aspects:

- Technical strength: The company has many years of experience in producing brushless motors and a professional R&D team, which can develop high-end products that meet market demand.

- Product quality: The company has a sound production process and quality control system to ensure stable and reliable product quality.

- Service capability: The company provides services such as DC motor selection, customization, maintenance, as well as technical support and after-sales service, which can fully meet the needs of customers.

Motor Characteristics details

Application scope of 60MM series DC brushless gear motor

The 60 series brushless DC deceleration motor can be widely used in various applications that require precise control and large torque output, such as robotic arms, vending machines, smart access control, smart homes, security equipment, medical devices, smart robots, etc. Due to its advantages such as small size, light weight, high efficiency, low noise, and long service life, the 60 series brushless DC deceleration motor is widely used in the drive systems of various intelligent devices.

The advantages of the 60mm series DC brushless gear motor

The 60 series brushless DC deceleration motor has the following advantages and characteristics:

- High efficiency: Brushless DC reduction motors do not require the friction and electromagnetic interference of traditional brushes, reducing rotor losses, improving operational efficiency, and increasing energy utilization efficiency.

- Long lifespan: Adopting a brushless DC motor increases its lifespan. Manufacturers’ high-quality and precision machining can greatly reduce friction and wear, thereby improving motors’ service life and operational reliability.

- Strong stability: Brushless DC motors do not experience sliding friction during operation, and their speed is stable, resulting in smoother motion and reduced shaking caused by sudden start-up and other factors, thereby improving system stability.

- Low noise: Compared to traditional DC motors, brushless motors have less noise due to the absence of worn brushes.

- Multiple specifications: The 60 series DC brushless reduction motor has multiple specifications and can provide different models and model combinations according to different customer needs to meet the needs of different equipment.

- Small size and light weight: Due to the use of brushless technology, this series of motors is more compact than traditional motors, with smaller size, lighter weight, and greater output torque, making it suitable for various compact design devices.

- Easy to control: Compared with traditional motors, brushless DC motors have higher control accuracy. They can be digitally controlled as needed, making it easier to accurately control the motor’s rotational speed and torque output.